LED (LIGHT EMITTING DIODE)

LEDs are currently the most efficient light source, very small, shatterproof and non-destructive (when operated correctly) and are now used virtually everywhere in many different wattages and sizes.

Conventional vs. HI-CRI

The CRI index refers to the quality of light, i.e. how faithfully it displays the colors of illuminated objects. It ranges from 0 to 100. Conventional LEDs have a CRI type of. 70, HI-CRI LEDs usually have an index of at least 90. At the same time, they have a slightly lower light output. They are suitable for work, specific activities, for people with poor eyesight, but of course not only for them.

List of LEDs we currently use

- CREE XP-L2 LED - the most efficient LEDs in 3x3mm size, reaching up to 220lm/W. We use a model with a colour temperature of 4500K or 4000K (neutral white) and T6, W2 and W3 bins. This LED series is more efficient than the popular and used Cree XP-G3 or Cree XM-L2 and XM-L3.

- Samsung LH351D - we use a variant with a colour temperature of 5000K and a CRI index of 93. They have only 12% lower light output than the XP-L2, T6, but produce an absolutely snow-white glow with no shades and accurate color. On the same TIR optics they produce a narrower and more defined center than the Cree XP-L2 so they are often combined with wider optics.

Many different variations

LED elements are produced by several large manufacturers, besides Cree, also Osram, Nichia, Lumileds (Phillips), LG, Samsung and Seoul Semiconductor. There are large printed circuit board chips and small chips, white and coloured, weak and the most powerful in sizes from 1x1mm to 25x25mm. It certainly does not mean that a bigger LED is better or that it shines more. Each has a different application.

Square LED chips in sizes 3-5mm are suitable for small power supplies. Reflectors or TIR optics are still small enough for these LEDs. Larger LED chips need larger optical elements. For larger LEDs it is already a big problem to direct the light into a narrow enough beam that does not create artifacts (circles, sharp transitions).

LED lifetime

CREE, whose XP-L2 series LEDs we use in our headlamps, specifies a lifetime of 50,000 operating hours, after which the original luminous flux drops to 70%. This time is calculated and estimated according to a methodology based on a sample of 6000h and refers to a passing current of 3A, for lower currents the lifetime is even higher. I.e. if someone with a headlamp shone for one hour every day, this reduction in luminosity would occur after approximately 99 years. So neither you nor we have to worry about this. LEDs, if well cooled, will last forever.

You may have had a previous bad experience with LED strips in your kitchen, where they gradually stopped working one by one before they all stopped glowing. That's a completely different thing than the LEDs in headlamps. The strips tend to have poor quality chips, the passing current is set too high, the strip itself has large thermal transients and is poorly cooled. The LEDs gradually degrade with heat and then go out after one. You don't have to worry about that with headlamps.

LED efficiency

The efficiency of an LED - how much it shines - depends mainly on the current you supply it with.Each LED is most efficient at a low current. The more lumens you need from it, the worse its efficiency (its ability to convert the passing energy into light) gets.

For example, if a 100mA current is passed through a Cree XM-L2, bin T6 LED, it produces a lumen output with an energy to light efficiency of 180lm/W. But at 1A only 145lm/W and at maximum current 3A only 102lm/W. The top of the range of LEDs is the XP-L2 series, which we use in all our lights. These achieve record efficiencies of up to 200lm/W at low current.

From this point of view, it is therefore very advantageous to have more LED chips in the light that do not operate at their limits. Exactly so that their efficiency is at its highest.

The second, less important, factor is the temperature of the LED. The lower the temperature of the LED (= the better the heat is dissipated away), the more efficiently it works.

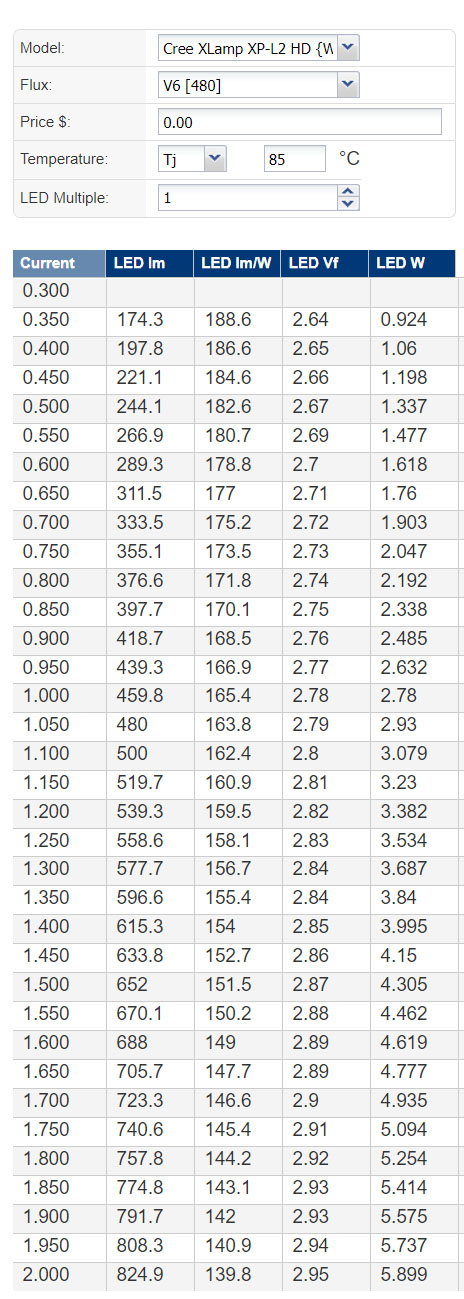

This is a printscreen of an XP-L2 LED from the pct.cree.com website, where you can easily see the voltage, lumens and efficiency (lm/w) of this LED at different currents and chip temperature.

Light cones and light focusing options

The LED itself produces a 125° light cone. This is very large, so the light needs to be directed through an optic or reflector. With both, a reasonable cone width can be achieved while greatly improving the range into the distance. Wider illumination aids orientation in space, and a large range is useful for safe cycling at higher speeds. Conventional reflectors usually have a reflective layer of aluminium with an efficiency of around 70%. The cover glass, depending on the material and the number and composition of the anti-reflective layers, also transmits only 92%-96%. A better option is to use TIR optics, which have an efficiency of up to 93% and do not need to have any additional cover glass in front of them. TIR optics are made from PMMA, which is itself quite hard. The cone from these optics is much smoother from the center to the edges and has no sharp transitions. Many current - even branded - lights use reflectors, and while the resulting light cone reaches far, it doesn't have the necessary peripheral illumination.

We chose TIR optics, which provide a cone with smooth transitions and no artifacts. The efficiency and size is higher than reflectors where there is additional loss on the cover slip. In headlamps we combine multiple different scatterers for perfect illumination of both edges and long range. At the same time we do not use additional coverslips and even so the headlamps are waterproof. This is made possible by our know how, which we don't even call by crazy English names. Our solution is ideal for sports and recreational use and the resulting light cone is great.

The colour of the light

Thecolor (temperature) of the light is another important thing. Manufacturers produce multiple so-called tints - i.e. the colour shades of the diodes. The most efficient diodes are always blue or green coloured (6500K or more) and this is also why many cheap flashlights glow bluish. Diodes with a neutral colour tint come to the market in the same efficiency much later. However, the color temperature of the light dramatically affects the ability to discern true-to-life shapes and colors. This makes it possible to distinguish rocks, branches and other obstacles when cycling or running in the field.

We currently use XP-L2 LEDs from American Cree with a colour temperature of 4500K in our headlamps. We consider these to be completely colour neutral, with high display quality and the feedback from our customers confirms this. We have also used 4000K and 5000K LEDs in the past, and we consider the current ones to be the best.

Color rendering - CRI (Color Rendering Index)

A common problem with LEDs is a low colour rendering index (CRI). CRI takes values from 0 to 100 and defines how faithfully the light renders colours. A light bulb has a CRI of 100. LEDs have a CRI between 65 and 95, those above 90 are referred to as HiCRI. For photography or filming, lights with a CRI above 90 are used exclusively. The following figure shows the differences between the different CRI values.

Figure 4: Image taken from https://ledspots.org/color-rendering-index/

The inferior display of some colours is because the LED does not generate light at all wavelengths equally intensely. The human eye can perceive wavelengths from 390nm to 700nm, so the extremes of this spectrum are unlikely to affect colour rendering. However, the problem is the dip in emission around 480nm (blue) and the unevenness of the whole spectrum.

Figure 5: Image taken from the Cree XM-L2 datasheet.

Conventional single-chip diodes (XP-L2, XM-L2, XP-G2 etc) have this index of 70-75 at a color temperature of 5000K. Colder shades can have as low as 65 and this is low and causes color washout (desaturation). Manufacturers are able to produce LEDs with high color rendering index (Cree produces with CRI 90), but unfortunately not so powerful. For example. XM-L2 with a color temperature of 3000K and HiCRI (CRI=90) shines with 1/3 less intensity than the 5000K variant.

In our Lucifer headlamp we use the most powerful XP-L2 diodes from Cree. We now use a color temperature of 4500K, which we consider a nice neutral white color with a CRI index of 70. We used to offer diodes with a CRI90, but not anymore. That's because these existing ones are just great and shine really well. We are not ruling out a CRI90 option again in the future and will monitor any new LEDs that come along.

However, the CRI Ra index suffers from imperfections, it is calculated based only on a shift of 8 pastel colours. So it does not address, for example, the deep red colour R9, which is important in filming, photography, art or medicine. Thus, other colour quality indices have gradually been developed, e.g. CRI2012 or CQS. CRI2012 is calculated from 17 saturated colours. CQS (Color Quality Score) calculates its Qa index based on 15 colours

Here you can see a typical spectroscopic measurement output of a Cree XP-L2, 4000K, CRI90, bin U5 LED.

LEDs are divided into multiple performance bins, depending on how much light output they produce at a given current. We currently use the highest bin available, V6. You can of course get much cheaper bins V5 and V4, which have 93% and 85% light output respectively, but we don't want to do that. We always try to sell headlamps with the latest technology, even if it costs something.